As a high-precision sensing device, the absolute pressure sensor of the inflation pump can monitor and adjust the pressure change during the tire inflation process in real time to ensure the accuracy and stability of the inflation. By integrating this technology, the pump can not only complete the tire inflation task in a short time, but also effectively avoid tire damage or under-inflation caused by pressure fluctuations during the inflation process. In addition, with the development of intelligent technology, the absolute pressure sensor of the inflation pump can also be linked with the vehicles intelligent system to achieve more accurate tire management, which further enhances the safety and driving performance of the vehicle.

Catalog

1. Working Principle of Absolute Pressure Sensors in Air Pumps

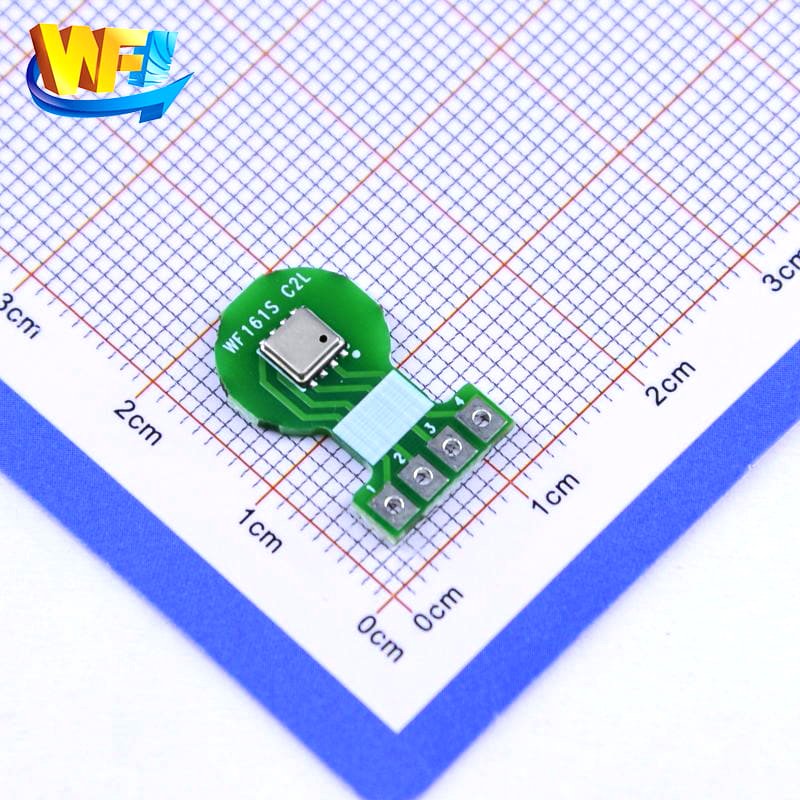

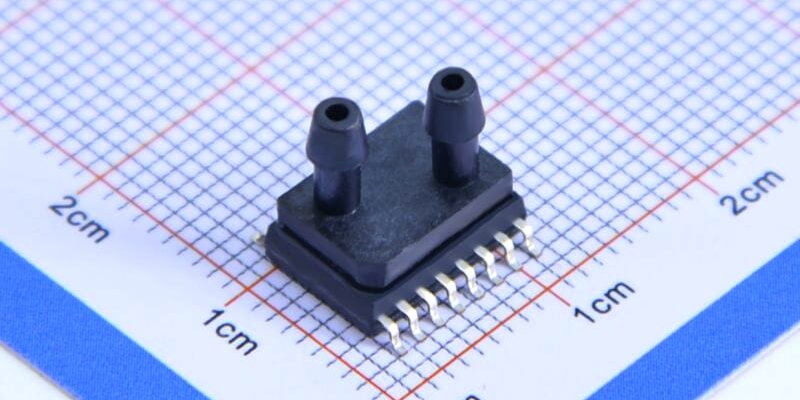

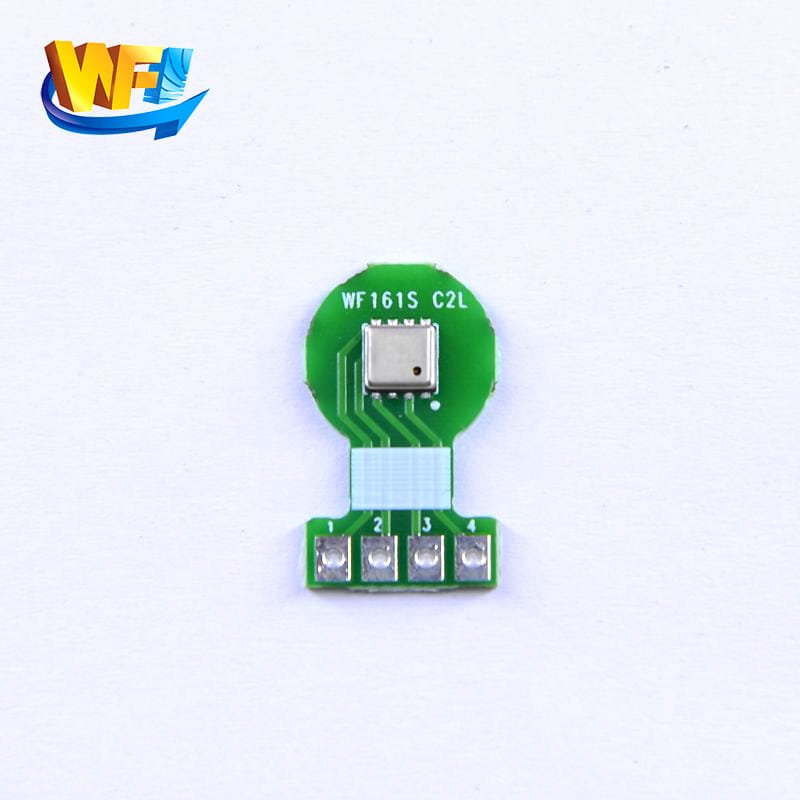

Absolute pressure sensors are designed to detect changes in gas pressure, operating based on principles such as the piezoresistive effect, piezoelectric effect, or capacitive effect. These sensors convert pressure variations into electrical signals for output. Unlike conventional sensors that measure gauge pressure, absolute pressure sensors measure pressure relative to a vacuum, thereby providing accurate readings that are not influenced by ambient atmospheric conditions. During the tire inflation process, as air flows through the sensor’s measurement port, the sensor produces an electrical signal proportional to the pressure. This data is then transmitted to the control system, which adjusts the air pump’s output in real time to maintain the optimal tire pressure, preventing both under- and over-inflation.

2. Advantages of Absolute Pressure Sensors in Air Pumps

1. Enhanced Inflation Accuracy

Traditional tire inflation methods often rely on manual judgment, which can lead to over- or under-inflation. With real-time pressure monitoring, absolute pressure sensors provide precise data to the system, allowing the air pump to quickly and accurately reach the preset pressure, thereby minimizing human error and ensuring precision.

2. Improved Inflation Stability

Environmental factors such as temperature fluctuations and external pressure changes can cause variations in tire pressure during inflation. Absolute pressure sensors deliver continuous feedback on pressure changes, enabling the control system to adjust the air pump’s output dynamically. This closed-loop control ensures that the inflation process remains stable and consistent, avoiding the risks associated with pressure fluctuations.

3. Extended Tire Lifespan

Maintaining the optimal tire pressure is crucial to preventing uneven wear and reducing the risk of blowouts. By precisely controlling the inflation process, absolute pressure sensors help maintain the ideal tire pressure, reducing wear and tear and ultimately extending the tire’s service life, while also enhancing overall driving safety.

4. Increased Driving Safety

Tires are the only point of contact between a vehicle and the road, and their pressure directly affects vehicle handling. Under-inflated tires may increase the contact patch, leading to excessive friction heat and a higher risk of blowouts; over-inflated tires, on the other hand, reduce contact area and grip. With its real-time monitoring and adjustment capabilities, the absolute pressure sensor ensures that tire pressure remains within safe limits, thereby significantly boosting driving safety.

3. Application Scenarios

1. Automotive Tire Inflation

The most common application of absolute pressure sensors is in automotive tire inflation. Previously, drivers relied on manual pressure checks and adjustments. Now, intelligent inflation systems equipped with these sensors can automatically detect and adjust tire pressure, greatly enhancing both efficiency and accuracy while reducing the potential for human error.

2. Automotive Maintenance Services

In automotive repair shops, a large volume of vehicles require tire inflation checks. Traditional manual methods can result in inconsistent or inaccurate pressure levels. Air pumps fitted with absolute pressure sensors ensure that each vehicle’s tires are maintained at the optimal pressure, improving service quality and operational efficiency.

3. Drone Inflation Systems

With the rapid development of drone technology, absolute pressure sensors are also finding applications in drone inflation systems. During flight, drones can experience significant pressure changes. By integrating these sensors, the system can adjust the pressure in real time, ensuring flight stability and safety under varying environmental conditions.

4. Technical Challenges and Solutions

1. Stability in High-Temperature Environments

Extended driving periods can lead to elevated tire temperatures, which may affect sensor performance. Manufacturers are addressing this challenge by using high-temperature-resistant materials and optimizing sensor packaging to enhance reliability under high-temperature conditions.

2. Waterproof Performance

Moisture or water ingress during the inflation process can disrupt sensor operation. Improving the sensor’s sealing structure and using waterproof materials can effectively prevent moisture penetration, ensuring reliable performance in diverse environments.

3. Cost Control

Currently, high-precision absolute pressure sensors are relatively expensive, limiting their widespread adoption in lower-end models or small-scale devices. Continuous technological innovation aimed at reducing production costs, while maintaining high accuracy and reliability, is essential for broader market penetration.

Conclusion

As a cutting-edge technology, absolute pressure sensors in air pumps play a pivotal role in enhancing tire inflation stability. By offering precise pressure monitoring and real-time feedback, these sensors ensure that tires are inflated to optimal levels, thus prolonging tire life, enhancing vehicle safety, and reducing maintenance costs. With ongoing advancements and cost reductions, absolute pressure sensor technology is poised to become an integral component in smart, automated automotive systems—delivering safer and more convenient driving experiences for vehicle owners.

The above introduction only scratches the surface of the applications of pressure sensor technology. We will continue to explore the different types of sensor elements used in various products, how they work, and their advantages and disadvantages. If you’d like more detail on what’s discussed here, you can check out the related content later in this guide. If you are pressed for time, you can also click here to download the details of this guides air pressure sensor product PDF data.

For more information on other sensor technologies, please visit our sensors page.