With the continuous advancement of IoT (Internet of Things) and smart devices, the demands on pressure sensors for accuracy, stability, and energy efficiency have steadily increased. The BMP280 sensor, widely recognized in the market for its maturity, has begun to show limitations under stringent environmental conditions or when high-precision requirements come into play. To address these issues, we conducted a systematic assessment and testing of the WF280A pressure sensor. By comparing WF280A and BMP280 from multiple perspectives, we aim to provide project developers and product designers with an in-depth reference for their selection process.

Catalog

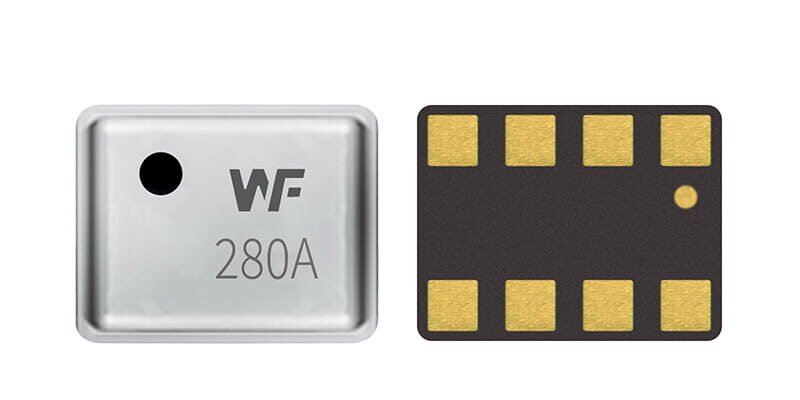

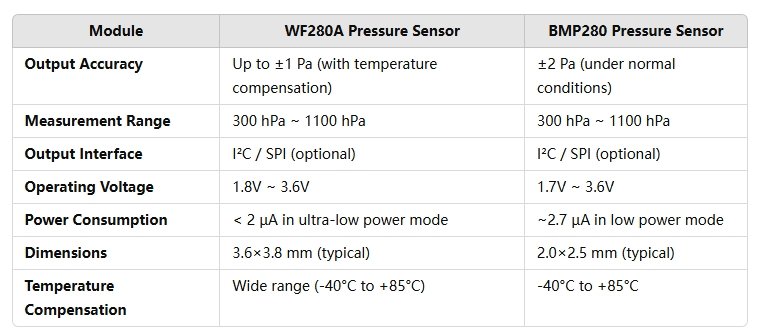

Technical Parameter Comparison

Note: The above data is sourced from the manufacturer and our lab testing. Actual parameters may vary depending on the operating environment and calibration methods.

Performance Feasibility Analysis

1. Accuracy and Stability

- The WF280A features a more advanced calibration algorithm and a high-precision ADC, yielding higher sensitivity to minor pressure variations in real-world testing.

- While the BMP280 is stable in general applications, it may exhibit larger deviations in high-altitude or rapidly changing temperature scenarios.

2.Temperature Range Adaptability

- The WF280A remains relatively stable from -40°C to +85°C, offering stronger compensation capabilities for sudden temperature shifts.

- The BMP280’s temperature compensation is relatively basic, requiring additional external calibration or protective design in extreme temperature environments.

3. Power Consumption and Response Time

- The WF280A draws less than 2 µA in ultra-low power mode, significantly reducing power consumption for battery-operated systems.

- Although the BMP280 also supports a low power mode, real-world tests indicate slightly higher average current usage, which can lead to increased energy costs in long-term battery-powered devices.

4. EMI Resistance and Structural Design

- The WF280A draws less than 2 µA in ultra-low power mode, significantly reducing power consumption for battery-operated systems.

- Although the BMP280 also supports a low power mode, real-world tests indicate slightly higher average current usage, which can lead to increased energy costs in long-term battery-powered devices.

Applications and Testing

1. Meteorological Monitoring and High-Altitude Usage

- In a lab-simulated high-altitude environment, the WF280A maintained consistently low data fluctuation over 72 hours, with a standard deviation around 30% lower than that of the BMP280.

- If the BMP280 is used at high altitudes without further temperature and pressure compensation, significant drift may occur.

2. Indoor and Outdoor Environmental Monitoring

- Thanks to its resistance to temperature and humidity variations, the WF280A offers higher data reliability in outdoor applications such as smart agriculture or environmental monitoring.

- The BMP280 may experience data offsets in regions with extreme temperature and humidity fluctuations, requiring periodic recalibration.

3. Wearables and Handheld Devices

- Because of the WF280A’s lower power consumption, it’s better suited for handheld or wearable devices that must operate continuously or rely on small batteries.

- Although the BMP280 is smaller in size, its comparatively higher power draw may not be optimal for applications with stringent battery life requirements.

Cost and Compatibility

1. Cost Advantages

- Under similar volume conditions, the WF280A and BMP280 have comparable unit prices. However, the WF280A’s higher level of integration can reduce additional circuit design and external compensation costs.

- Over the long term, the WF280A’s stability and low power consumption can help save on maintenance expenses and battery replacements.

2. Pin and Package Compatibility

- Both WF280A and BMP280 share similar I²C/SPI interfaces, and manufacturers typically provide reference schematics for straightforward replacements.

- Although there is a slight difference in package dimensions, the overall layout adjustments during PCB design are manageable.

3. Software Support

- The development approach for WF280A and BMP280 drivers is quite similar; only minor adjustments are needed for initialization and calibration parameters.

- Most popular MCUs (STM32, Arduino, ESP32, etc.) can easily integrate either WF280A or BMP280.

Replacement Considerations

1. Calibration and Compensation

- The two sensors have slightly different internal algorithms. After switching to WF280A, re-check your calibration process and confirm whether the temperature and pressure compensation parameters still fit your needs.

- In extreme environments (e.g., high altitude, significant temperature variations), ensure your calibration routine is comprehensive to avoid measurement inaccuracies.

2. Waterproofing and Durability

- If the device will be exposed to outdoor or high-humidity conditions, consider adding waterproofing, venting, and dust protection in the enclosure design.

- The WF280A shows robust durability under high humidity, but protective design should still be tailored to the application scenario.

3. Software Adaptation

- Although the interfaces are similar, you must adapt your code to match the WF280A’s register configuration and initialization steps.

- Thoroughly test the data reading process and error range to ensure a seamless fit with existing system functions.

4. Program Compatibility

- If you already have a BMP280-based project, you can copy over related code modules and modify them as needed.

- Pay attention to function calls that manage sensor standby, wake-up, sampling rates, etc., as these may need slight adjustments.

Conclusion and Recommendations

Recommendations:

- High-Altitude or Extreme Environments: If your deployment involves high altitudes, cold climates, or rapidly fluctuating temperatures, prioritize the WF280A for stable measurement data.

- Battery-Powered Systems: For products emphasizing battery life, the WF280A’s ultra-low power mode can significantly reduce power consumption.

- Quick Replacement: If you have existing hardware designs for the BMP280, note the package dimension differences when migrating to the WF280A and make necessary adjustments in your driver code.

Overall, the WF280A has the comprehensive performance and ease of use to serve as an excellent replacement for the BMP280. If you’re looking for a new-generation pressure sensor to enhance your product’s competitiveness, the WF280A is an outstanding choice that combines high precision, low power consumption, and robust stability.

The above introduction only scratches the surface of the applications of pressure sensor technology. We will continue to explore the different types of sensor elements used in various products, how they work, and their advantages and disadvantages. If you’d like more detail on what’s discussed here, you can check out the related content later in this guide. If you are pressed for time, you can also click here to download the details of this guides air pressure sensor product PDF data.

For more information on other sensor technologies, please visit our sensors page.